My PiHPSDR MK II Project

My PiHPSDR Controller MK II rev 2 Project

Return to Home Page

page last updated

09/19/2020

Latest updates 9/19/2020

Updates on my experiences and some minor errors that I found while getting PiHPSDR to work.

The larger 38mm Rotary encoders [Enc-6]

like the LPD3806-600bm-g5-24c.

These parts will short out the +5V for the

Enc-1 if the Encoder Washer, below, or Kapton tape on the PCB,

is not used to isolate the large

metal ring on the top of the encoder. This gives the effect of a

failed IC2

LMZ22005TZ and can ruin the IC2 and the PCB. Also these

encoders are specified to run from 5V to 24V

and of the 4 that I have they

ranged from 5.05 - 5.1 Volts minimum. Unfortunately my LMZ2205TZ

did

not put out enough "+5V" to make them work. My surviving IC2 puts out

4.99V subject to the

accuracy of my inexpensive DMM. I ended up using

a 5.6k Ohm resistor from the switched 13.8V to pin 1

of the encoders which

was an easy solution. The math on the LMZ2205 data sheet would indicate

that

the expected voltage would be between 5.06 and 5.12 VDC, depending upon

the inclusion of R7 or not.

For the board that I over reworked, I used

a self contained

Buck Converter module from Amazon

that has 5A adjustable output [3/$8]

to replace IC2. If you would like a description of how these encoders work,

follow

the link that follows

Rotary Encoder Teardown. Be sure that you enable the pull-ups

for

the Enc-6/1 and save the settings or the amount of excess "5V" will not make

any difference.

There is an error in the instructions of

the pihpsdr-install.pdf which indicates that you should disable I2C.

If you

do disable I2C the new controller software will not start. It will

begin and then drop back to the RPi desktop.

So ENABLE I2C to get the

software running.

After many false starts I have both PCBs

functioning. I was experiencing some unusual behavior so

I decided

that a fresh clean install would correct some of my initial incorrect

settings, which it did.

The units are behaving much better now. To

facilitate the update I made a text file,

PiHPSDR_install_script.txt, to

eliminate the tedious typing of the commands in the terminal window.

Just put the file in

documents and open it to copy and paste the desired

command string in the terminal window.

I am now "printing" the side panels for the

case. There are 4 side panels that are needed

and each is 5 inches

long. They will be glued together to make two 10 inch sides.

Each

piece takes about 3 hours to print. If you are interested the stl

file is below.

PiHPSDR_Side

Channel_v4.stl

The large holes in the ends are for 4-40 brass inserts and

alignment pins in the center where the glue will be applied.

New files: from 9/1/2020

Updated BOM:

PiHPSDR_Controller_MK_II_rev.4_BOM.xlsx

3D Parts:

ALPS_Concentric_Knobs_3.stl

Note:

Large encoder may short out +5V with out the spacer below

Encoder_Washer_Spacer.stl

Shaft_extn.stl

for large encoder

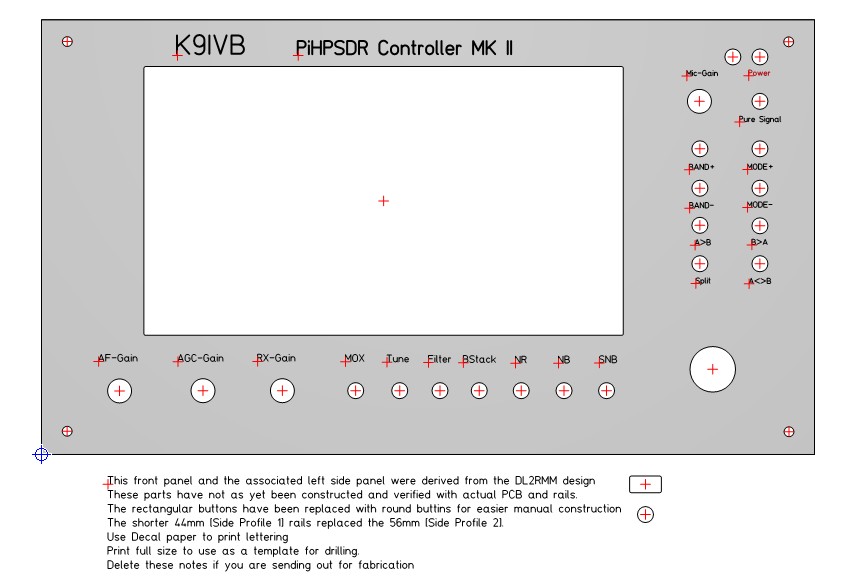

New prelim Front Panel Files:

K9IVB

PiHPSDR MKII FrntPnl Holes-prelim_6112020.xlsx

K9IVB_vFP_drill_06102020.drl

PiHPSDR

MKII_rev3_K9IVB_FP.fpd

I have two functional units but have some

difficulty getting the buttons and encoders configured.

It is suggested that you also look at the older info below for some explanations.

I do have a 3D printed side rail design to

go with the faceplate.

It requires 4 pieces, two to a side that will need to

be glued together

Current design files are available at https://github.com/g0orx/pihpsdr

The information below is a supplement based upon my construction approach.

A commercial version of this unit will become available from:

https://apache-labs.com/al-products/1054/Controller-V2.html

Updates 6/2/2020

6/7/2020

6/13/2020

6/17/2020

Below is the front panel I plan to

construct, but with some different graphics.

Changed the rectangular push buttons to round to make home

construction easier.

There are two Front Panel Express design files in the

BOM_Extra

Info_05032020.zip

download along

with an X , Y drill file [PiHPSDR_FP_Holes_K9IVB_05032020.pdf].

I have not been able, so far, to

reconcile the drill file for the Front Panel with the PCB drill file with

any degree of accuracy.

In the future I plan to glue a copy to a piece of

cardboard and drill out the holes after I finish building up my 2 PCBs

I am planning to convert to all English measurements: 10" x 5 1/2" to 6" panel, still subject to change.

* * * * * *

The attached [almost] fully sourced BOM and

other preliminary information

will provide some choices between the

rectangular pushbuttons and the round style

with some alternative case

construction ideas.

Note: After putting down the 42 10K 0805

resistors on the "front panel side" [they do just fit]

of the PCB I

have concluded that the parts should have been 0603 [Mouser #

603-AC0603FR-0710KL].

Also missed counting

R10 which is 0805 !

Will correct BOM after finishing assembly & test.

Two BOM errors

D2

should be BAS16J [Mouser # 771-BAS16J115] not BAS16W [wrong footprint]

L1,2,3,4

completely wrong part, should be Mouser # 623-2743021446 [last digit 6 is bulk 7 is T/R]

Another part error

R2 on

Schematic is 620 Ohm and BOM is 680 ohm.

620 Ohm is correct value to get 5V.

Still another error

The

2x20 header needs to be at least 13.58mm high so that the USB sockets clear

the PCB

PiHPSDR_Controller_MK_II_rev.2_BOM_05022020.pdf

The BOM also has a choice of 4 dual rotary

encoders or 4 single rotary encoders

which are interchangeable up until you

solder them into the PCB.

* * * * * *

If a couple of zeros after the first

significant digit of the Front Panel Express parts do not scare you off, you

might consider ordering the parts from that vendor. The DL2RMM design

has a deeper case and provision for a Hermes-Lite 2 as well.

NOTE: If

you are using the large 38x35mm D encoder [ENC6] you will need the bigger

Profile 2 extrusions.

My approach will be to use some hobby

plywood [1.5mm / 0.062" thick] or some window acrylic type material which is

much easier to hand machine than the aluminum, especially if you want the

small rectangular pushbuttons. This material could be used for front and /

or back panels and sides with the Front Panel Express Side Profile

Extrusions. Another alternative is to just get some 3/8" to 1/2" thick

hardwood [256mm / 10.08" Long] from Home Depot for the sides.

I am also

redoing the panel to be 10x6in [254x125.4mm] which will be easier to

construct

in the USA and will permit the use of wood sides.

Note: 1. the Left

hand side of the actual PCB should be only 0.07874in [2mm]

inside the panel,

so that there is easy access to the Raspberry PI outputs.

2. Leave some

clearance at the top of the panel for the other Pi I/O

which also overhang

the top edge of the PCB.

Home Depot has some "plastic" sheets:

Plaskolite

Non-Glare Picture Glazing UPC # 074507996548 8"x10"x0.050" @ $3.68

Optix Acrylic Sheet UPC # 769125010218 0.93"x11"x14" @ $6.67

Also 0.25":x2.5"x24" Poplar Board UPC #

728927310285 @ $2.58

Also now considering making 3D Printing [.stl] files for the side panels to fit FPE & wood sides.

* * * * * *

The original gerber files are available from github. See the link at the top of

the page.

I ordered my boards from JLCPCB and they had an issue with

the file extensions..

These drill files have never appeared in any gerber file

viewer that I have used, with out modifications.

Below is a copy of the gerber files that I used to

order my boards.

The only changes that were made were to the file extensions.

The Rev

2 artwork properly grounds the three address pins [14, 15,& 16] on IC1 the

MCP23017

PiHPSDR_MK_II_Rev.2_JLCPCB_Gerber.zip

Notes:

1. Any Gerber file is completely readable in any text editor.

2. They usually contain comments, with some descriptive information about the files.

3. If you wish to decode the actual data, not in the comments, you will have to refer

to the Gerber and Excellon formatting documents [see links below].

4. https://www.ucamco.com/en/gerber

5. Spec: The_Gerber_File_Format_specification.pdf

6. Excellon: https://gist.github.com/katyo/5692b935abc085b1037e

Free On-line Gerber Viewer: https://gerber-viewer.ucamco.com/index.html

* * * * * *

Stay tuned

You can contact me with QRZ info